2025 Corporate Sustainability Update: Environment

American Vanguard is committed to providing solutions for growers around the world to sustainably support the needs of the growing global population – which is expected to increase by 25% over the next 30 years. Through focused improvement efforts regarding our own operational footprint, we are committed to be part of the global solution to reduce the overall impact on the environment through our focused improvement efforts that minimize energy consumption, greenhouse gas emissions, waste generation, and water consumption at our manufacturing and laboratory facilities. Our comprehensive system to capture all environmental aspects of our operations has allowed us to closely monitor changes and provide a foundation for us to establish and measure progress on future aggressive goals for our organization. Importantly, we have obtained limited assurance for several environmental indicators from an independent third party, as further detailed in our 2025 Corporate Sustainability Report. Highlights are presented below,

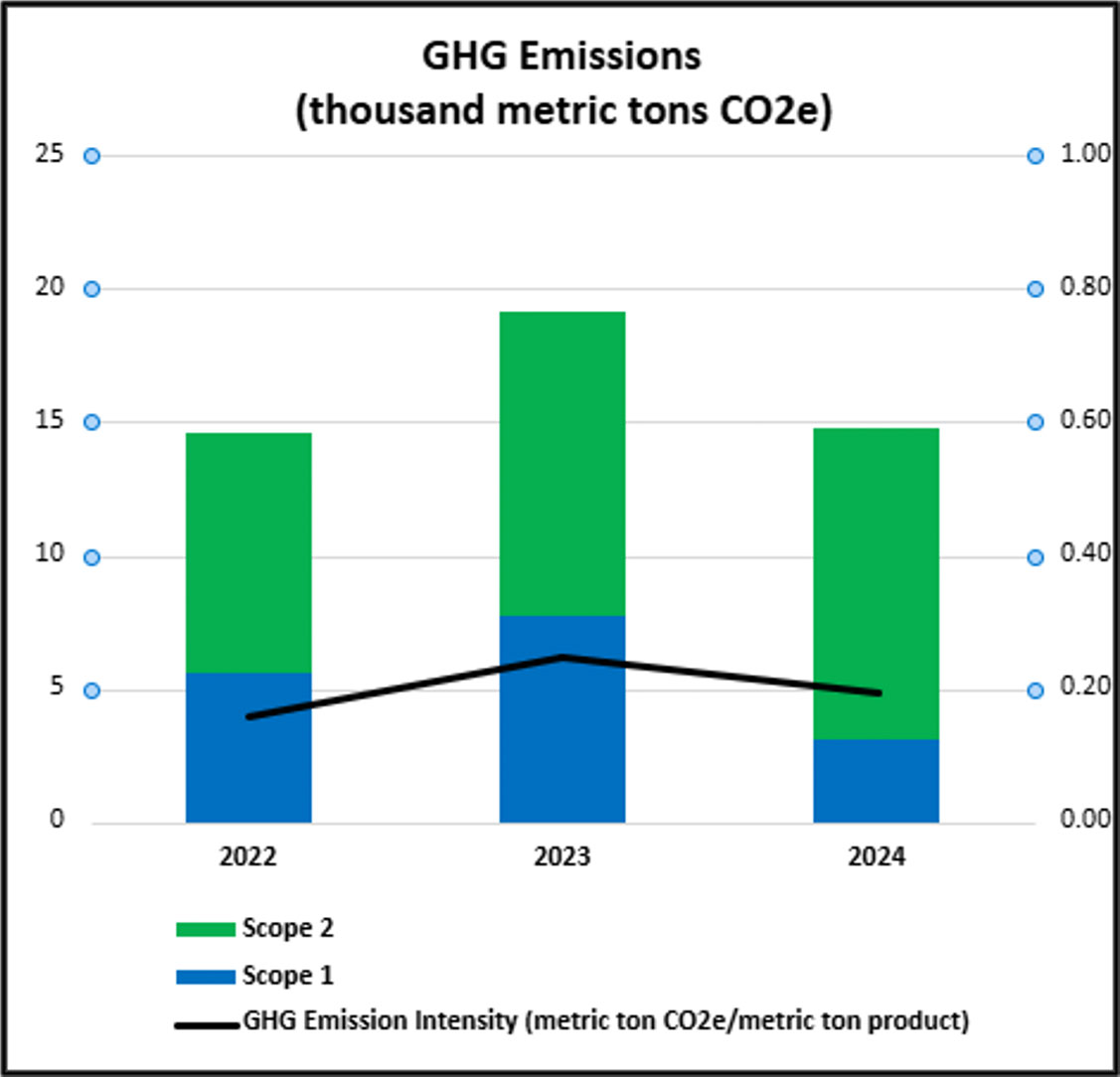

Greenhouse Gas Emissions

Our greenhouse gas emission inventory includes both Scope 1 (from direct combustion and refrigerants) as well as Scope 2 (from indirect sources such as electricity and purchased cooling water and steam). A substantial reduction to Scope 1 emissions is attributed to the reduction of refrigerants in 2024. Overall GHG Emissions and Intensity were lower in 2024 versus 2023. GHG Emission Intensity is calculated using ton of finished product ready for sale as managed in American Vanguard’s inventory management software.

See Performance Table for Supporting Data

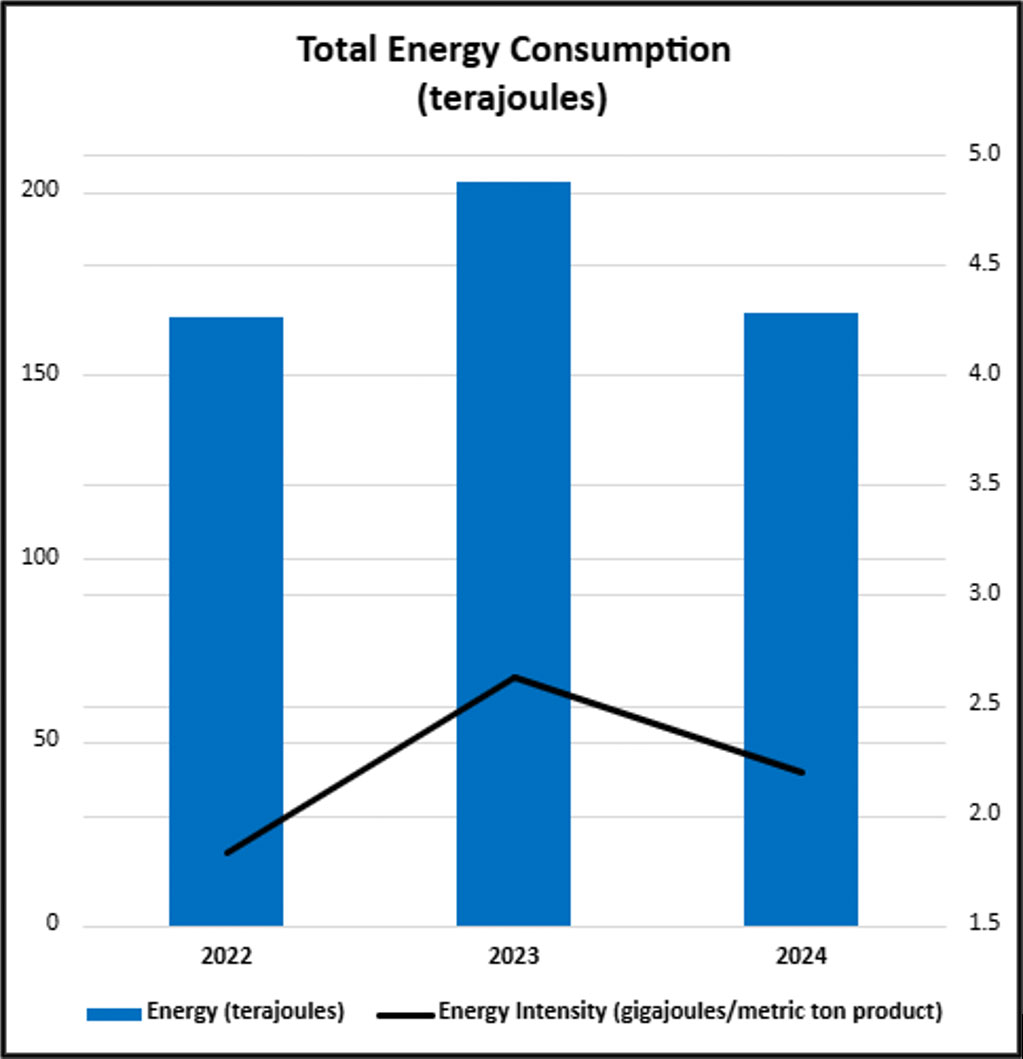

Energy

The energy we consume for our production, formulating, and laboratories is comprised of: electricity; purchased steam and cooling water; and natural gas and other fuels (such as diesel, gasoline, and propane). A capital project to upgrade and replace a main chiller unit resulted in over 3,000 pounds less of refrigerant recharge in 2024, as well as a 40,000 gallon reduction in diesel required for the generator to run the backup unit. Energy Intensity is calculated using ton of finished product ready for sale as managed in American Vanguard’s inventory management software.

See Performance Table for Supporting Data

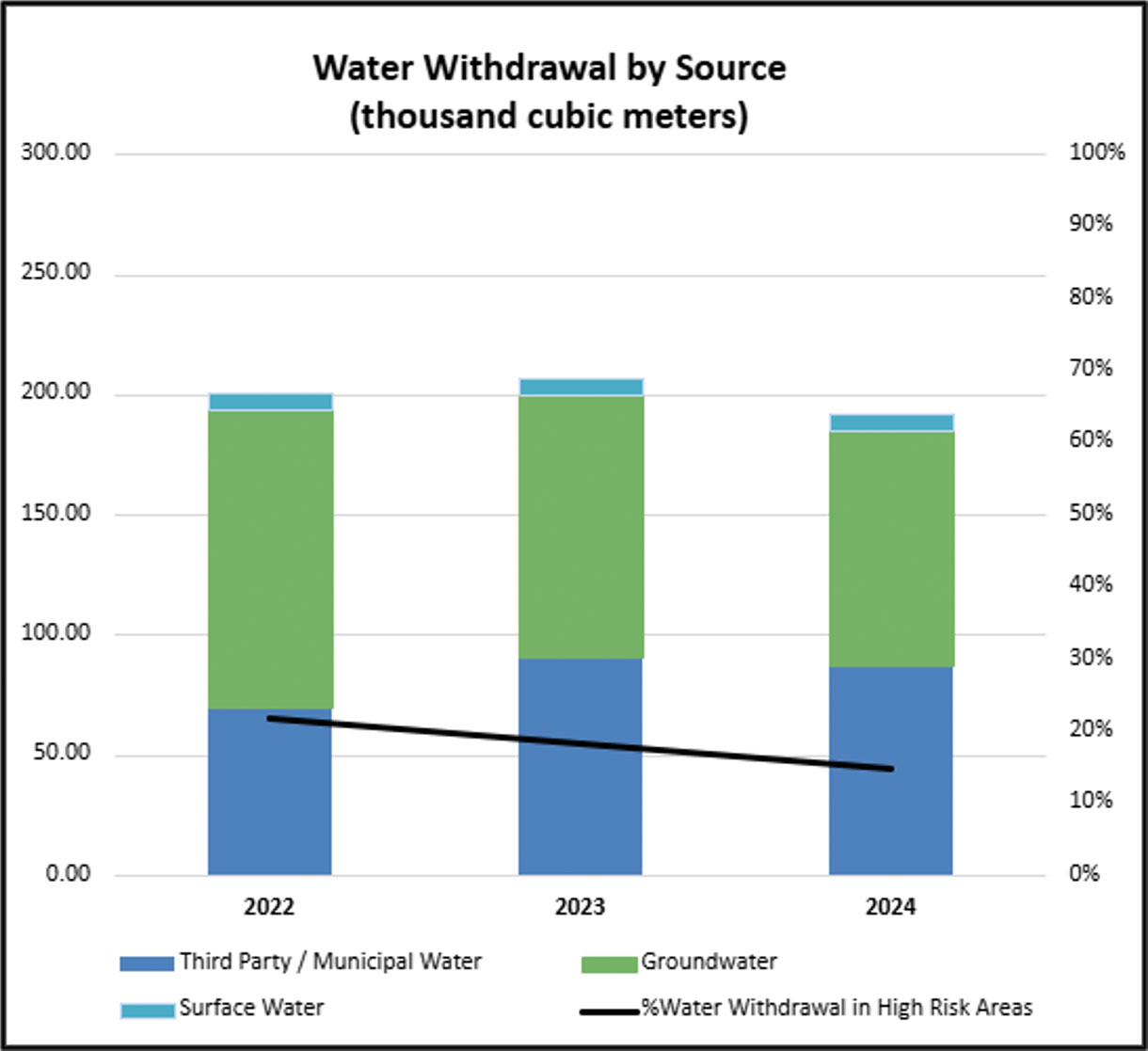

Water

While some of these data are currently estimated, efforts are underway to install meters where possible to provide the usage detail for identifying and prioritizing specific opportunities for future reductions in overall water withdrawal and consumption.

Additionally, we conducted a thorough water risk assessment of all manufacturing and laboratory sites in 2022 using the Aqueduct Water Risk Atlas tool. Two areas were identified as high risk, and we have prioritized these locations as focus areas for American Vanguard. For example, being well aware of the water stress in their region, one of these two sites (located in Los Angeles, CA) had already begun an initiative to reduce water use in 2021. The team developed and implemented a stormwater capture plan to maximize the amount of rainwater that can be captured and used within the facility. The plan included modifications to install additional filtration systems and equipment to efficiently capture the rainwater and enable transfer of the water to processing areas. The rainwater replaces the amount of municipal water that was used in production. The facility layout is designed to capture an estimated 57,800 gallons per rain event.

See Performance Table for Supporting Data

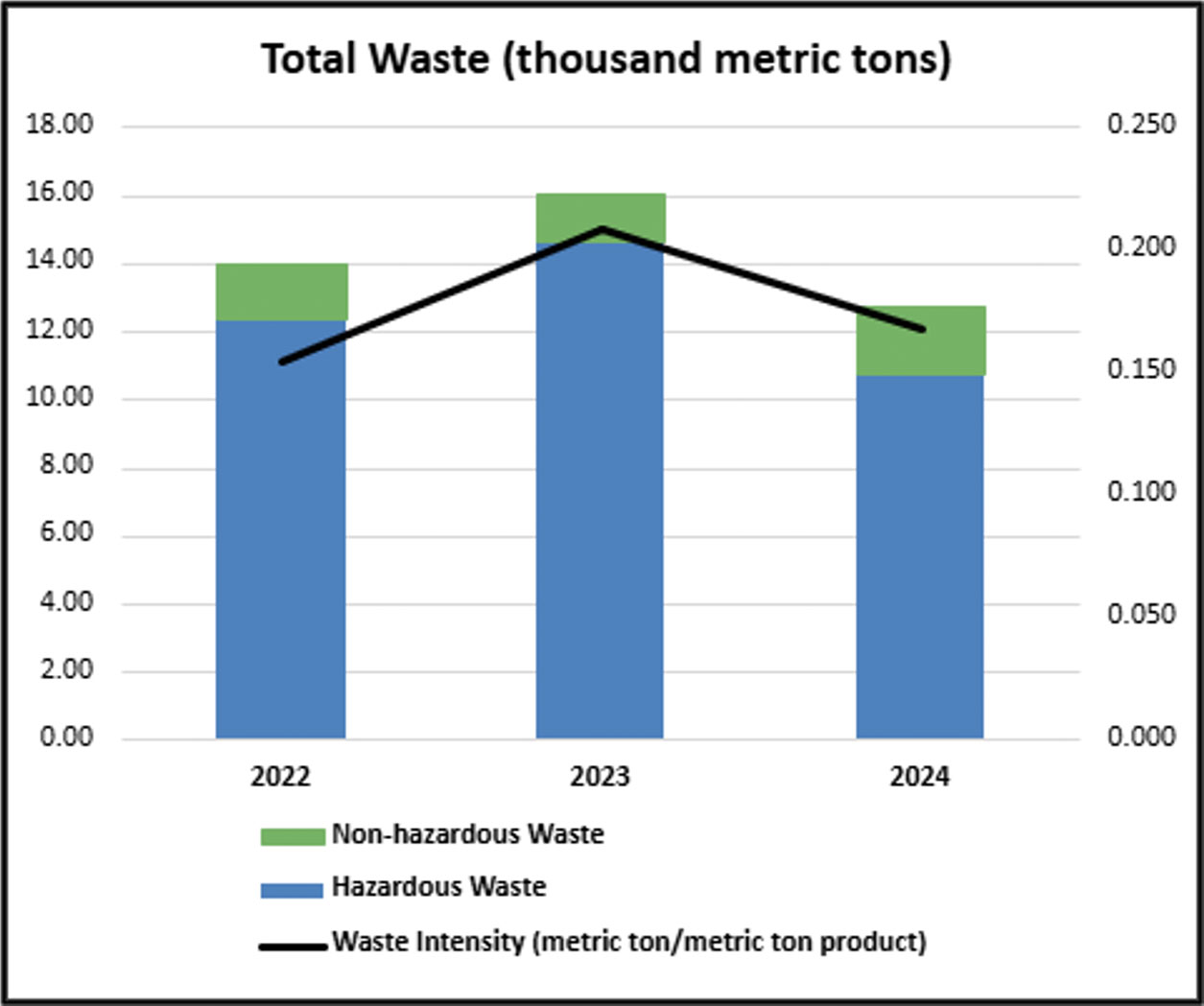

Waste

This graph depicts a summary of our total waste accounting classified as Hazardous and Non-hazardous along with the resulting Waste Intensity. We are capturing these data across all our manufacturing and laboratory operations, research farm, tolling operations and warehouses, and as shown here, have experienced a decrease in total waste generated as well as waste intensity in 2024 as compared to 2023.

See Performance Table for Supporting Data